A world away, an example set

By Dave Copeland

TRIBUNE REVIEW

Sunday, January 25, 2004

ESSEN, Germany — On a rainy Sunday afternoon, hundreds of Germans flock to Zeche Zollverein, a collection of red brick buildings that was built in 1932 and was once called the most beautiful mine in the world.

At its peak, 12,000 tons of coal was unearthed at Zeche Zollverein every day, but no coal has been mined since 1986. Today, Zeche Zollverein is a leading tourist attraction in the Ruhr region in western Germany and considered a prime example of converting an industrial site to a multiuse facility.

One building houses the Red Dot Design museum, which showcases the best designs of everything from cell phones to automobiles to utensils — everything including the kitchen sinks — all against the backdrop of a five-story building once used to process coal, with much of the original machinery intact. Next door, visitors can catch a meal or a drink in a turbine room-turned-restaurant.

Other parts of the facility include office space, artist studios and, by 2006, a new building will be constructed to house what backers hope will be one of the leading design schools in Europe. On Monday, winners of an International business plan competition presented plans aimed at making the complex self sufficient when government funding amounting to 110 million Euros ($136.2 million) runs out in 2006.

“It would be much easier to build a new building and perhaps it would cost less. But this is only one part of our perspective,” said Professor Dr. Ulrich Borsdorf, director of the Ruhrland Museum, which plans to open a new facility on the site by 2007. “The idea is to reuse the old buildings for a new purpose.”

Whether it’s a former steel mill converted into a nightclub or a former train station that is now a lunch counter, there are scores of examples of “creative reuse” of historic structures in this former industrial region of Germany. Perhaps because so much has been lost — in the nearby industrial center of Dortmund, nearly 95 percent of the city’s buildings were destroyed or damaged by Allied bombers during World War II — there is a deep-seated desire among urban planners here to preserve old spaces and places.

“It’s protected as a cultural heritage area. You cannot tear it down,” Borsdorf said.

It’s a stark contrast to Pittsburgh, where almost all of the idled steel mills that once lined the region’s rivers were torn down in the 1980s and 1990s.

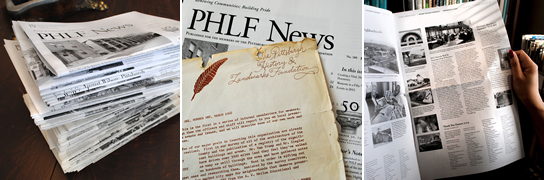

“We tried, but we were always turned down,” Arthur Ziegler, president of the Pittsburgh History & Landmarks Foundation, said of local efforts to do what has been done in Essen and other parts of Europe. “To me, I think it’s tragic that a city with this international reputation as a great steel center did not capitalize on that — just because you build a lively museum doesn’t mean you’re living in the past.”

Even before the Jones & Laughlin mill on the South Side closed, Ziegler had approached officials with the idea of building a restaurant that would give diners a view of the mill’s electric arc furnace in action. The idea was shot down for liability issues, but once the mill closed, Ziegler tried to push forward plans to save some of the mill buildings for museums, restaurants and other uses.

“For some reason the leadership thought we needed a new image,” Ziegler said. “But it doesn’t matter where you live on the planet, if you think of iron and steel, you think of Pittsburgh. If people will go to St. Louis to see an arch, they’d certainly come to Pittsburgh to hear this story.”

All of the buildings on the South Side mill site have since been torn down. Today the city Urban Redevelopment Authority is working on LTV South Side Works, a mixed-use brownfield redevelopment project completely reliant on new construction.

“They’ve spent a great deal of money on redevelopment and boosting its image as something else,” Ziegler said. “But by trying to make yourself into every other place, you fail to distinguish yourself from every other place.”

Casino Zollverein, the restaurant in the turbine room in Essen, is perhaps a close approximation of what Ziegler envisioned for the South Side Works. Rows of tables are perched on former catwalks, and original equipment serves as a backdrop to meals prepared by a chef known for marrying “new” German cuisine with local ingredients.

Other buildings at Zeche Zollverein house artists’ studios, exhibit space, performance venues, offices and Museum Zollverein, a traditional museum that chronicles the history of the mine itself.

But officials charged with redeveloping Zeche Zollverein don’t want the facility to be seen as a tourist attraction, even with the long skating rink next to a battery of idled coke ovens. Dr. Wolfgang Roters, managing director of the private development company overseeing Zeche Zollverein’s transformation, said Saturday that the former coal mine would be a business center that also offered various recreational amenities.

The winning business plans, including one from a team from the Joseph L. Rotman School of Management at the University of Toronto and a team from the ESADE Business School in Barcelona, include concrete ideas for business attraction and retention, including a focus on developing a business cluster in Essen centered on the design industry.

A team from the Wharton School at the University of Pennsylvania was among the 11 finalists in the competition.

In its first life, Borsdorf said, Zeche Zollverein was considered one of the pre-eminent coals mines in the world. All of the buildings were built in the Bauhaus architectural style, and the miles of railroad tracks, machinery and refining equipment were coal mining’s equivalent to Henry Ford’s assembly line.

“The machinery allowed for (continuous) mining of coal, which had not been done before. There is a certain architectural beauty, because at other (mines) there are different styles that reflect the succession of time,” Borsdorf said. “But Zollverein was done by two men in two or three years, and therefore I think it merits the title of heritage area.”

No one is quite sure why the 247-acre mine site was spared by Allied bombers during World War II. Borsdorf suspects it was because it was relatively easy to rebuild and restart a levelled coal mining facility, prompting attacks in the region to be focussed more on steel mills owned by Krupp Steel.

For Ziegler and other local historic preservationists, the only remaining hope for preserving at least a portion of Pittsburgh’s steel-making heritage lies in the center of 110 vacant acres along the Mon River. What remains of the Carrie Furnace, which opened in 1884 and closed in 1983, occupies 35 acres of that land.

A bill that has already passed the U.S. House of Representatives and could pass the U.S. Senate this year would pave the way for preserving the site, said August Carlino, executive director of the chairman of the nonprofit Steel Industry Heritage Corp., which oversees the Rivers of Steel National Heritage Area in Rankin, Swissvale, Braddock and North Braddock.

The bill would allow the 35 acres that contain the rusting buildings to be preserved and maintained as a national park, while the surrounding 75 acres is being eyed by the Allegheny County economic development department for a mixed-use office and recreational development that would complement the nearby Homestead Waterfront.

Once the legislation is approved, the National Parks Service would have up to three years to formulate a plan for preserving and reusing the site. That plan would need to go back to Congress for approval.

“Hopefully it won’t take that long,” Carlino said. “A lot of the engineering studies are already complete.”

Carlino envisions an interpretive museum taking advantage of some of the latest museum display technologies to recapture some of the power of the former steel mills. The history of Pittsburgh’s role in the industrial revolution, as well as the plights of workers, would be documented as well. But time could be working against the efforts, Carlino said.

“The buildings and furnaces have sat out there for close to 20 years. They’re in a deteriorated state, but not in a state of imminent collapse,” Carlino said. “There are catwalks I would be reluctant to put anybody on, but that’s part of the (Parks Service) plan for the site — how do you circulate people through those structures so that the power of that now-closed mill will be conveyed to people?

“If we succeed, it will be quite remarkable,” he said.

Alfred Krupp’s influence

Pittsburgh had Andrew Carnegie, and Essen had Alfred Krupp.

Perhaps best known to Americans as the steel company that made guns and armaments for Hitler’s armies, Krupp Steel’s influence in Europe at one time rivalled that of U.S. Steel Corp.’s influence in North America.

In recent years, Krupp has merged with Hoesch Steel of Dortmund, Germany and Thyssen Steel, also in Essen, to form Thyssen Krupp Steel.

Krupp built weaponry for four German wars, and it was so formidable by World War II that nearly two thirds of the company’s plants were either destroyed or damaged by Allied bombers. A third generation leader of the company, Alfred Krupp von Bohlen und Halbach, was sentenced to prison by an American military court for the company’s role in arming the Nazi regime.

He was released in 1951 and returned to the firm’s management in 1953. Historians have said the military tribunals were reluctant to hand out overly harsh sentences to industrialists in hopes of speeding up reconstruction efforts.

Even while the Krupp family built a huge private fortune, Alfred Krupp, the second-generation leader of the company and the family member credited with building the company’s prominence in the late 1800s and early 1900s is held in high regard for becoming one of the first European industrialists to offer “womb-to-tomb” benefits. He became one of the first industry titans to offer company health insurance, pensions, subsidized housing for employees and company-owned stores.

Alfred’s father, Friedrich Krupp, founded the company to process English cast steel in 1811. Upon his death in 1826 — when Alfred was just 14 — the company was debt-ridden. Alfred Krupp focused the company on producing the highest quality steel possible, and by 1887, the company employed more than 20,000 workers and Alfred Krupp had earned the nickname “Cannon King.”

In addition to building the first diesel engine and the first steam turbine locomotive, Krupp Steel made wheels and rails for American railroads and produced the steel plating for New York City’s Chrysler Building.

Dave Copeland can be reached at dcopeland@tribweb.com or (412) 320-7922.